Making jigs and things – Lathe Steady

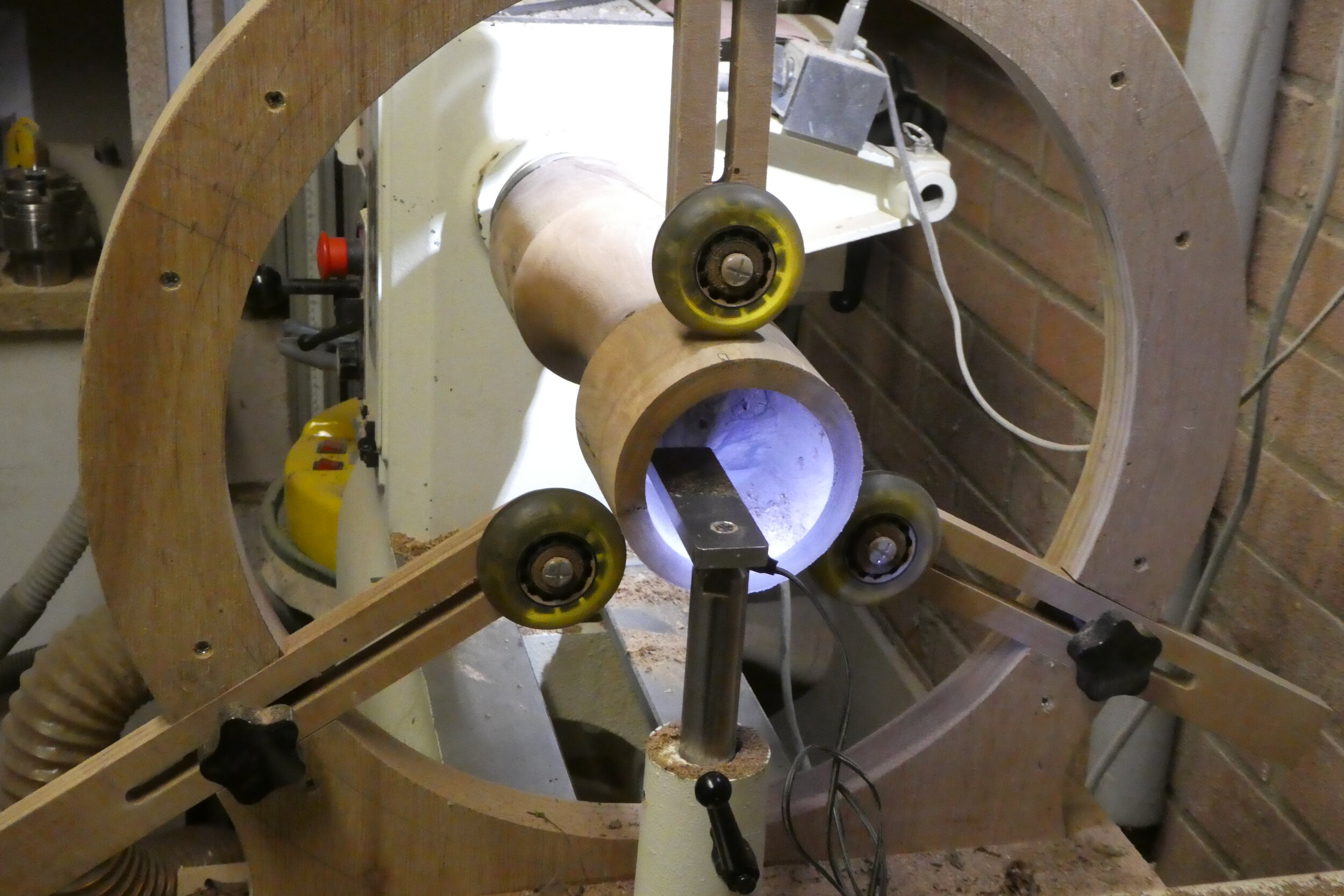

Some time ago I showed a lathe steady at the club which was made from plywood and recycled roller blade wheels. I went to a boot fair one Sunday morning and found some good quality roller blades that had seen better days but had good wheels with little wear and tight bearings and got them for £3 as I recall. I was only interest in the wheels and discarded the boots. I little bit of design work and looking at similar homemade steadies on Pinterest, I made my steady to match the centre height above my lathe bed. Have a look at the pictures showing the steady in situ with a long modern style church candlestick which I needed to support to hollow out the end.

It worked perfectly having centred everything up and because the wheels are all bearing mounted, the rig was able to support quite high lathe speeds with no vibration, wobble or overheating. It was happy around 1500 revs although I tested it to 2000 revs without a problem. As always with homemade jigs great care and attention must be given to the rig at all times and non aggressive cuts are essential to keep undue stress laterally. The support arms accommodate quite large pieces (at slower speeds of course) and lock into place with wing nuts. The arm supports are simply a double layer of ply with slots cut across so that the arm cannot swing out of line.

Ted Higgs